Key takeaways

- Canon launches the corrPRESS iB17, an industrial inkjet press designed for corrugated packaging production, offering offset-like quality on boards.

- The press enables cost-efficient short to medium runs with fast turnaround times and minimal operator intervention.

- Canon expects to make the corrPRESS iB17 available in the US in 2027, supporting its expansion into the digital corrugated packaging market.

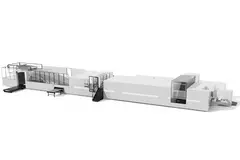

Canon USA has introduced the Canon corrPRESS iB17, an inkjet press engineered for industrial-scale corrugated packaging production. It aims to support corrugated converters that have to deliver shorter runs with more variants, faster turnaround times, and premium quality.

The corrPRESS iB17 delivers offset-like quality directly onto corrugated boards up to 1.7 m wide with water-based inks and primer for indirect food contact.

The company says it allows cost-efficient short- to medium-length runs with “ultra-fast turnaround times and requires few operators and low-level skills compared to conventional technologies.”

Kiyoshi Oka, executive vice president and general manager of marketing strategy unit at Canon USA, says: “With the corrPRESS iB17, Canon is making a confident entry into the corrugated packaging space, bringing fresh innovation backed by decades of inkjet expertise. This press is built to help converters streamline production while achieving consistent, high-quality results — even for food-safe applications.”

“Its industrial design and automation make it a smart fit for today’s fast-paced environments. We’re excited to offer a solution that not only meets current demands but also opens the door to new possibilities in digital packaging. It’s a strong reflection of Canon’s long-term commitment to this industry.”

Cost-efficient solution

The inkjet press enables converters to achieve cost-efficient production, extending digital printing viability. The press is supported by automated printhead cleaning and quality control systems, which reduces operator intervention while boosting production efficiency.

The system’s design is said to cut waste through efficient print-on-demand and eliminates the use of printing plates and chemicals.

The system also uses “an advanced spot primer that produces optimal ink adhesion and color reproduction across the full range of corrugated materials.” According to the company, the ink is jetted onto the board after the primer application without any drying in between, reducing the impact of drying on the board and contributing to a highly reliable production process.

The system supports coated and uncoated boards up to 1.7 m and 1.3 m, and ranges from 1 mm to 8 mm thick, at a linear speed of 80 m per minute.

Canon says it owns all the key components in the printing process, including printheads, inks, and drying. This allows Canon to enhance the system’s performance more easily.

The Canon corrPRESS iB17 is scheduled to be available for purchase in the US in 2027.