ISM & ProSweets 2026: Packagers bring premium design and AI to confectionery

Key takeaways

- Premium product presentation is becoming a strategic priority, with packaging solutions enabling customization and individualized formats.

- Automation, AI, and robotics are increasingly shaping confectionery packaging, with exhibitors showcasing robot-compatible molded fiber solutions and AI-supported process control.

- Recyclability and waste reduction are central themes, with suppliers showcasing innovation processes in the sustainability chain.

ISM & ProSweets will open its doors to visitors in Cologne, Germany, next week. Packaging industry experts will present their latest technologies reflecting the confectionery industry’s accelerating focus on efficiency, sustainability, and premium product presentation.

Ahead of the event, February 1–4, we sit down with packaging exhibitors to explore solutions tackling the confectionery industry’s technical and market challenges.

Manuel Leibrock, chief marketing officer at Papacks, tells Packaging Insights: “We are observing a clear trend: packaging is increasingly becoming an integral part of brand strategy.”

Papacks aims to address the industry’s growing need for packaging solutions that meet the demand for product protection and brand presentation.

The company offers fully individualized solutions in the Advent calendar segment. Leibrock shares that the Advent calendar market has undergone “a fundamental transformation” in recent years.

Ulma Packaging is developing cost-saving solutions that adapt to the specific needs of its customers.“Brands are increasingly using this format to position 24 of their products as a premium gift — ranging from cosmetics and spices to spirits and, of course, confectionery. This development requires packaging solutions that ensure both high-quality presentation and food safety.”

Ulma Packaging is developing cost-saving solutions that adapt to the specific needs of its customers.“Brands are increasingly using this format to position 24 of their products as a premium gift — ranging from cosmetics and spices to spirits and, of course, confectionery. This development requires packaging solutions that ensure both high-quality presentation and food safety.”

Premium presentation meets efficiency

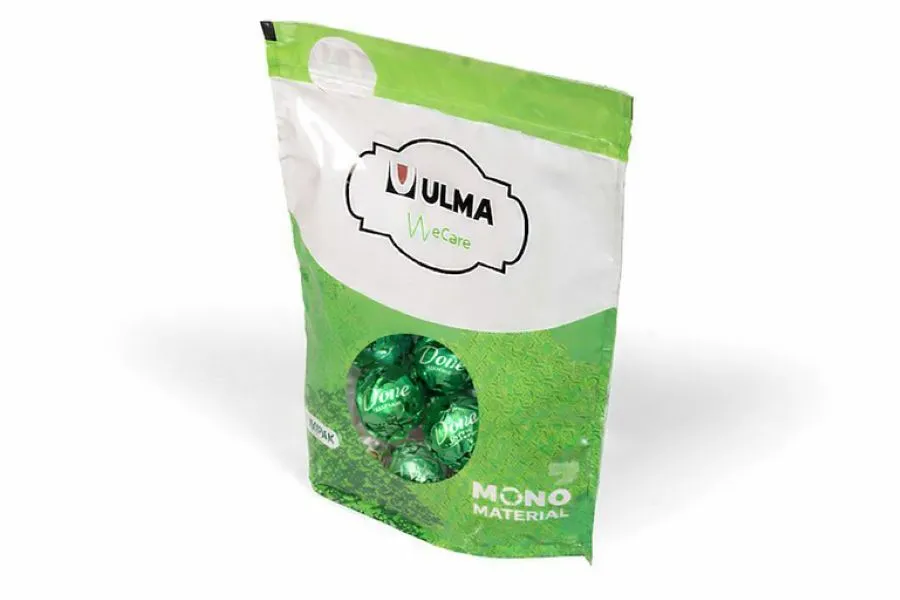

Ulma Packaging highlights the importance of combining efficiency and product presentation. The company will showcase its vertical doypack-style packaging solution at the event.

“The system enables doypack-style packaging with a premium finish, comparable to pre-formed solutions, enhancing the product’s perceived quality at the point of sale. The innovative cutting system eliminates film waste, saving 4 mm of film per pack. This not only reduces material consumption but also enhances the sustainability of the process,” the company shares with us.

The solution improves efficiency by forming the packages directly on the line. According to Ulma, manufacturers can save up to 50% compared to using pre-formed doypack pouches, reducing costs without compromising packaging quality.

Meanwhile, Rovema is supporting confectionery brands’ packaging efficiency by presenting its vertical form fill and seal machine BVC 250 Candy.

“It can produce various bag shapes and is compatible with different packaging materials — from mono and multilayer packaging materials to paper and paper composite packaging materials. The intelligent design and innovative features make the packaging process even simpler, faster, and safer,” says the company.

Robotics and AI integration

At this year’s tradeshow, Papacks will present individually customizable three-dimensional forms made from molded fiber. According to the company, these forms can be adapted to specific product geometries and are developed for use in automated production lines.

The solution is compatible with robotic systems and enables the packaging to be integrated into existing manufacturing processes.

“The robot-compatible design of our molded fiber forms enables their use in automated production lines. Particularly with larger volumes starting from 100,000 units, automation plays a decisive role in production speed,” says Leibrock. Papacks’ packaging solution is made from natural virgin fibers.

Papacks’ packaging solution is made from natural virgin fibers.

Peter Désilets, managing director and co-founder at Pacoon Sustainability Concepts, tells Packaging Insights that the company is presenting insights into AI integration in production processes at the event.

“Our partner, mts Contech, will show details and examples to implement AI in the development process and machine control. Participants can learn about how packaging processes can be secured using data, from materials such as recycled materials, bioplastics, film, to machine settings and live quality control.”

“A practical case study, for instance, cup production, will be used to illustrate cause-and-effect relationships and show how stable parameter windows can be found and concrete optimization strategies developed with just a small amount of data.”

Waste reduction and recyclability

Packagers point to sustainability factors, such as waste reduction and recyclability, as other central themes to be explored at ISM & ProSweets this year.

Rovema says it will present its smart reclosable pouch solutions, developed to extend shelf life and reduce food waste. “The carbon footprint of producing food is high, often many times higher than the material used to package it.”

“A zipper is much better at preventing gas exchange and keeping products fresh longer when compared to a clip or just rolling up the top of a snack package.”

Packaging concepts aim at reducing material use while maintaining performance and shelf appeal.Rovema also highlights that consumers of all ages can benefit from reclosability. “Easy-open packages for the elderly, portion control for adults, and child-resistant zipper features for families with young children mean there is a steadily growing range of package offerings incorporating these features.”

Packaging concepts aim at reducing material use while maintaining performance and shelf appeal.Rovema also highlights that consumers of all ages can benefit from reclosability. “Easy-open packages for the elderly, portion control for adults, and child-resistant zipper features for families with young children mean there is a steadily growing range of package offerings incorporating these features.”

At the tradeshow, Pacoon will be joined by partners across the supply chain, spanning coated paper production to recyclability solutions. Together, they will outline how the industry can transition away from foil-based packaging, often composed of multilayer laminates with limited recyclability, toward highly recyclable paper-based alternatives for the sweets and snacks sector.

“Discover how paper can be transformed into sustainable packaging today with clever barrier functions, precise moulding and intelligent machine technology, and then recycled as a valuable raw material in the waste paper cycle,” says Désilets.

“Delfort will present paper-based solutions for cookies, snacks, ice cream, chocolate, and other products. Sacmi will give insights into machine adjustments and the production of paper-based packaging,” he adds.

“FormerFab will present the importance of forming shoulders and the differences between foil and paper packaging processing. Interzero will share hints and hurdles for good paper packaging recycling.”