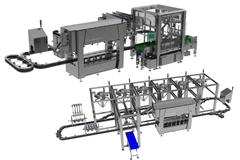

Herpak-Ulma launches high-speed tray-sealing line for ground-meat production

Key takeaways

- Herpak-Ulma has launched a high-speed tray-sealing application for the Mondini Trave Sinfonia, targeting high-volume ground-meat lines.

- Software-controlled magnetic transport enables up to 200 packs per minute, nearly doubling conventional grind-line throughput.

- Fully automated design removes belts and pushers, improving stability, hygiene, and changeovers, particularly for low-oxygen MAP formats.

Herpak-Ulma has rolled out a high-speed tray-sealing application for its Mondini Trave Sinfonia to enable high-volume ground-meat production. The solution is a fully automated alternative to conventional tray-sealing methods.

“The competitive ceiling for grind-line tray sealing is around 120 ppm. With Sinfonia, we can engineer a 200 packs per minute grind line — almost a 100% throughput increase,” says Carlo Bergonzi, product manager for Tray Sealing at Harpak-Ulma.

The machinery uses software-controlled magnetic-transport architecture to achieve its performance advantage.

“Sinfonia fundamentally changes what’s possible in ground-meat tray-sealed packaging. By controlling each tray independently, we remove the mechanical constraints that typically dictate line speed. The result is a faster, cleaner, and far more stable tray-sealing process that simply isn’t achievable with conventional systems.”

The design eliminates belts, pusher arms, and other friction-based components that typically constrain sealing speed, especially in low-oxygen modified atmosphere packaging applications.

“Given the momentum behind meat-brick formats across major retailers, this application directly addresses the performance conversations we’re hearing from processors as they head into The International Production & Processing Expo 2026.”

Competitive advantage

The machine includes portioning, dual denesting, retractable conveyor loading, and a 14-up sealing array. These are said to enable each processing station to run at an optimal rate without limitations caused by fixed-pitch conveyor mechanics.

The new high-speed tray-sealing Sinfonia application can help customers achieve a consistent, contamination-resistant tray path and simplified changeovers in a compact footprint.

Sinfonia’s capabilities are also said to differ from other similar solutions that rely on mechanical indexing systems that cannot independently control tray motion, and comparable throughput levels cannot be achieved with traditional technologies.

At Empack 2025, Ulma Packaging exhibited its TSA 680P tray sealer.