Fish-scale waste can be transformed into biodegradable plastic alternative, study finds

Key takeaways

- An MIT materials scientist has created a biodegradable, plastic-like material made from fish-scale waste.

- The project upcycles fish offal, producing thin, transparent films that can biodegrade within eight weeks.

- The work aligns with a growing research trend exploring food waste as a feedstock for next-generation bioplastics.

A materials scientist from the Massachusetts Institute of Technology (MIT), US, has engineered a new class of biodegradable, plastic-like materials derived from fish offal.

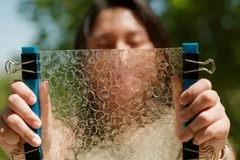

Jacqueline Prawira, a MIT senior student at the Department of Materials Science and Engineering, has focused on the scales of fish. By harnessing their natural structure, she has transformed the material into thin, transparent films suitable for grocery bags, packaging, and disposable utensils.

“Using biomimicry of the fish scale composition, calcium salts, and collagen, Cyclo.Plas 2 (CP2) is a novel alternative polymer with dual focus on tackling both plastic degradability and waste accumulation,” Prawira shared in her research on Youth STEM Matters.

Upcycling fish-market waste

In traditional Asian cooking, fish scales are typically discarded after butchering. Prawira’s inspiration came from the Asian fish market. She noticed that fish scales are fairly strong, thin, and flexible. They are also lightweight for their strength.

Her project, CP2, uses the biomineralization concept to valorise 3D-printed polylactic acid (PLA) waste with a fish scale-inspired mineral, hydroxyapatite, to form composites. The research found that the composites exhibited greater flexural strength compared to 3D-printed PLA waste and had faster degradation in hydrolysis, home composting, and acidic environments.

The project also adopts the sclerotization concept. The physicochemical properties of the intact collagenous matrix of fish scale waste were enhanced to form a thin, plastic-like material. According to Prawira, the thin films were comparable to low-density PE, offering high transparency and shrinkage. Trials have also revealed enhanced thermal stability and water resistance. Notably, the film biodegraded within eight weeks with low total dissolved solids.

“I’m hoping that we can have daily lives that can be more in sync with the environment, so you don’t always have to choose between the convenience of daily life and having to help protect the environment,” she says.

Researchers are increasingly exploring food waste as a resource for addressing the global plastic crisis. Last month, scientists from Monash University, Australia, developed a method to turn food waste sugars into natural plastic films that could replace petroleum-based packaging.

An earlier study also found that Honduran agro-food waste, such as taro, yucca, and banana, could provide a sustainable alternative to the overreliance on non-renewable resources and the lack of biodegradability in traditional plastics.