Edible fungus serves as waterproof coating for fiber-based packaging

Key takeaways

- Researchers from the University of Maine, US, developed a water-, oil-, and grease-resistant coating made from edible fungus.

- The film can be applied to materials like paper, denim, felt, and wood, showing potential for wrapping and cup coating applications.

- The team aims to optimize flexibility and scale production using existing systems.

Researchers have developed waterproof materials using edible fungus as an alternative to single-use plastic wrap and paper cup coatings.

The team created a film that blocks water, oil, and grease. In proof-of-concept tests, the film formed on everyday materials, including paper, denim, polyester felt, and thin wood, demonstrating its potential to replace plastic coatings.

Caitlin Howell, the corresponding author of the study from the University of Maine, US, tells Packaging Insights: “We believe the coating will be highly adaptable to different packaging formats. Because the cellulose–mycelium mixture can be diluted before growth, it can be applied by spraying onto three-dimensional shapes such as cups or trays.”

“When grown either directly on a substrate or as a free-standing film, the material is flexible under moderate humidity conditions, suggesting potential for use in wrapping or laminating applications.”

Inventing water-resistant materials

The report, published in Langmuir, reveals that growing cellulose nanofibrils based mycelial coatings onto paper or textile substrates could provide a scalable way to create water-resistant barriers.

The scientists aimed to develop a food-safe, natural film with water-, oil- and grease-resistant properties. To do this, they combined T. versicolor mycelia with a nutrient-rich solution of cellulose nanofibrils, then applied thin layers of the mixture to materials, such as denim, polyester felt, birch wood veneer, and two types of paper, allowing the fungus to grow in a warm environment.

The hyphal structure and surface hydrophobicity are playing a role in water barrier functionality.“At relative humidities below about 40%, the films can become brittle and may crack when creased. We believe we can overcome this limitation by reducing the coating thickness, which should relieve internal stresses during drying,” says Howell.

The hyphal structure and surface hydrophobicity are playing a role in water barrier functionality.“At relative humidities below about 40%, the films can become brittle and may crack when creased. We believe we can overcome this limitation by reducing the coating thickness, which should relieve internal stresses during drying,” says Howell.

“We’ve run some preliminary tests with thinner cellulose-only layers and have seen improved flexibility, leading us to believe that a similar optimization of our fungal–cellulose composite will provide reliable performance even when folded and creased.”

Potential for industrial applications

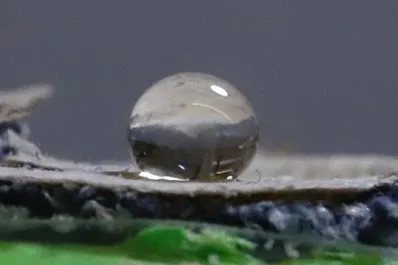

The US researchers say that water droplets placed on the fungus-treated textiles and paper formed bead-like spheres, while similar droplets on untreated materials either flattened out or were absorbed.

To scale this solution, Howell shares that the main technical challenge is maintaining a clean environment during the initial growth phase.

“The edible fungus establishes itself within the first day or two, and during that short window, any airborne contaminant, such as a mold spore, could compete with it. Fortunately, this is a well-known issue in food and fermentation industries and can be addressed using standard practices such as controlled humidity, filtered air, and surface sterilization without requiring aseptic conditions.”

“The other consideration is process integration: translating the laboratory growth step to a continuous or semi-continuous system. Because the coatings are already applied using scalable techniques such as blade coating or spraying, the next step is to adapt existing roll-to-roll or batch drying lines to include a short controlled-growth stage before drying and inactivation,” she explains.

Howell says that none of these hurdles is fundamental. With process optimization, the approach can be compatible with current paper and fiber-based packaging production lines.

“Our hope is that by providing more ways to potentially reduce our reliance on single-use plastics, we can help lessen the waste that ends up in landfills and the ocean. Nature offers elegant, sustainable solutions to help us get there,” she concludes.