Key takeaways

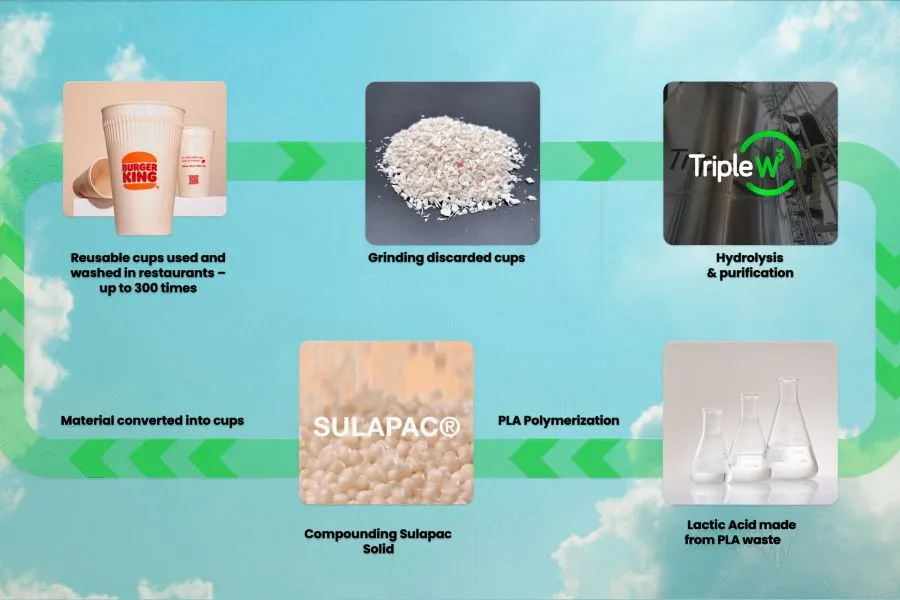

- Sulapac and TripleW have completed a closed-loop pilot showing that reusable cups made from Sulapac Solid can be commercially and chemically recycled.

- The pilot confirms that Sulapac Solid cups can be upcycled repeatedly through TripleW’s platform.

- The process demonstrates that fully bio-based, biodegradable materials can replace fossil-derived plastics in cups.

Sulapac has joined forces with TripleW, a Belgian innovator in circular biochemistry, for a closed-loop pilot, demonstrating that reusable cups made from Sulapac Solid can be chemically recycled on a commercial scale.

The upcycling system cycle eliminates the need for fossil-based materials. The pilot shows that the transition from single-use to reusable cups made from a fully bio-based and biodegradable material can be achieved without relying on fossil-based plastics.

Tal Shapira, CEO at TripleW, says: “We increase resource efficiency by using biological resources, and our clients can benefit from going circular.”

“Together with Sulapac, we’re showing that bio-based and compostable materials like PLA-based compounds are not just sustainable alternatives — they can be truly circular. The chemical upcycling scaleup utilizing the Sulapac cups, resulted in full recovery of the lactic acid — a building block of PLA.”

“Our approach is fully aligned with key European policies, from the Green Deal and the Circular Economy Action Plan to the upcoming Packaging and Packaging Waste Regulation. It exemplifies how circular bioeconomy innovations can position Europe as a leader in achieving circularity, reinforce industrial competitiveness, and offer scalable alternatives to fossil-based packaging.”

Alternative to oil-based plastics

Sulapac’s Sulapac Solid material is said to be dishwasher-proof and combines a “premium ceramic-like appearance with exceptional durability.”

The system is said to reduce raw material and logistics costs, as well as stabilize supply chains.The solution is compatible with standard plastic production processes and is a composition designed for repeated use on airplanes, cruise ships, and in quick-service restaurants.

The system is said to reduce raw material and logistics costs, as well as stabilize supply chains.The solution is compatible with standard plastic production processes and is a composition designed for repeated use on airplanes, cruise ships, and in quick-service restaurants.

In the pilot, used Sulapac Solid cups were collected, grinded, and broken down through hydrolysis into their building blocks, including lactic acid. Lactic acid can be utilized in applications such as personal care and pharmaceutical products, or it can be transformed back into a food-grade biopolymer.

The polymer-to-polymer recycling process allows the material to be reused repeatedly. The companies plan to grow the volumes of Sulapac Solid collected and recycled through TripleW’s platform.

Dr. Heidi Peltola, chief product officer at Sulapac, says: “It’s remarkable that one doesn’t have to choose between bio-based or recyclable packaging — you can have both, also when it comes to reusables.”

“This partnership is a tangible step toward a future where high-performance sustainable materials like Sulapac Solid circulate just like traditional plastics — but without the environmental burden.”