Confectionery packaging adapts to sustainability and cost challenges with paper and flexibles

Key takeaways

- Confectionery brands are weighing paper, aluminum, and flexible plastics to meet recycling rules while protecting product quality.

- Coveris, KM Packaging, and Smurfit Westrock share their insights, highlighting barrier performance, weight, and circularity limits.

- Cost pressures and consumer expectations continue to shape material innovation.

Amid tightening recycling targets and regulations, confectionery packaging is adapting to remain competitive and inexpensive. Paper-based solutions and aluminum foil are popular material choices, but flexible plastic packaging remains widely used for protection and moisture control.

Packaging Insights speaks to Coveris, KM Packaging, and Smurfit Westrock about their latest confectionery packaging solutions, focusing on the environmental validity of paper-based solutions, recycling regulations, and cost challenges.

“The confectionery sector demands a high level of creativity in shape and form, to win the highly competitive fight for consumer attention,” says Ian Lloyd, senior director for Consumer Marketing, at Smurfit Westrock.

“It takes imagination and a blend of science, physicality, and manufacturing capability to meet that demand and stand out on the shelf.”

Promising paper

Consumers expect first-rate unboxing experiences for their sweets and chocolates, presenting manufacturers with specific design requirements alongside regulatory demands.

The EU’s Packaging and Packaging Waste Regulation, which comes into force this year, requires manufacturers to adapt to recycled-content targets. Paper-based solutions offer a viable alternative that is increasingly popular, says Lloyd.

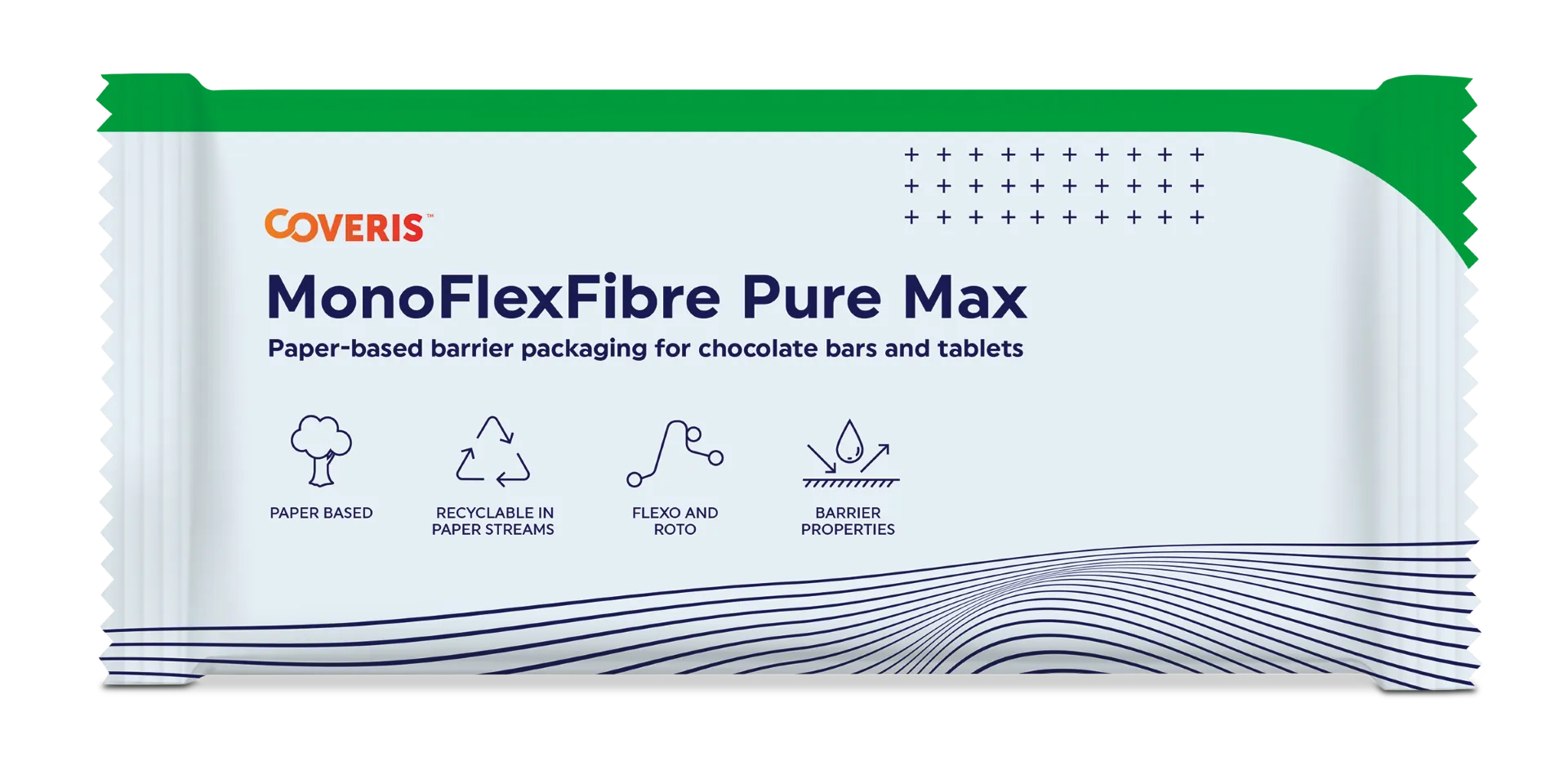

Coveris’s MonoFlexFibre Pure Max (Image credit: Coveris).For example, replacing plastic trays in chocolate boxes or redesigning solutions to facilitate easier separation of components for recycling are among the company’s solutions. Smurfit Westrock recently supplied seasonal gift packs for Christmas. These included paper tubes for premium confectionery, advent calendars, and the addition of novelty features such as decorative windowing on festive boxes.

Coveris’s MonoFlexFibre Pure Max (Image credit: Coveris).For example, replacing plastic trays in chocolate boxes or redesigning solutions to facilitate easier separation of components for recycling are among the company’s solutions. Smurfit Westrock recently supplied seasonal gift packs for Christmas. These included paper tubes for premium confectionery, advent calendars, and the addition of novelty features such as decorative windowing on festive boxes.

Meanwhile, Coveris’s MonoFlexFibre Pure Max is designed for chocolate bars, offering maximum barrier performance, efficient printing, and high impact shielding, highlights Melinda Bonamour, market development director for Flexible Paper at Coveris.

“Packaging needs to work within today’s recycling infrastructure while remaining adaptable to future developments. Designing solutions that cannot be effectively recycled at scale today risks undermining sustainability goals in the short term, even if they align with a longer-term ideal,” she says.

Furthermore, KM Packaging’s commercial director for Exports, John Shipley, highlights the benefit of paper-based solutions as there is an already established recycling stream across regions.

“At KM Packaging, we spend a great deal of time working on new product development and innovative new materials for recyclability and efficiency. Aluminium foils and paper already have their recycling streams established, and while flexible plastics aren’t widely recycled yet, we’re offering customers the opportunity to move from mixed polymers to our recyclable films in anticipation,” he adds.

Plastic preference

While paper solutions can help packagers meet recycling and regulatory requirements, Bonamour highlights that the material is “not automatically more sustainable.”

.webp) The confectionery sector demands a high level of creativity in shape and form, says Smurfit Westrock's Ian Lloyd (Image credit: Smurfit Westrock).She says: “Sustainability is currently driving the most significant transformation in flexible packaging, with the industry moving beyond lightweighting toward fully recyclable structures and the large-scale integration of recycled content.”

The confectionery sector demands a high level of creativity in shape and form, says Smurfit Westrock's Ian Lloyd (Image credit: Smurfit Westrock).She says: “Sustainability is currently driving the most significant transformation in flexible packaging, with the industry moving beyond lightweighting toward fully recyclable structures and the large-scale integration of recycled content.”

Shipley also suggests that paper solutions are often misunderstood.

“Paper does have the drawback of not being as light or durable as flexible plastic packaging, and there is a requirement to have a certain amount of virgin paper included in recycled paper for food contact, which means it is not entirely as circular as is commonly understood.”

He explains that while paper-based packaging benefits from having a well-established curbside recycling stream, the “real” aim should be to invest in flexible packaging recycling infrastructure and collection.

“The question isn’t about which material is more sustainable, but whether we’re using the right one for the job at hand.”

Designing for recycling

Technical challenges can arise when designing confectionery packaging, especially when balancing recyclability, consumer satisfaction, and protection, says Lloyd.

“Smurfit Westrock’s primary focus remains upon construction, design, and continuing to make the most proven products like folding cartons, shaped, and rigid boxes to create engaging and unexpected shapes and mechanisms.”

.webp) Coveris and Pladis partnered to switch to recyclable paper packaging for confectionery (Image credit: Coveris).Lloyd highlights how Smurfit Westrock aims to extend decorations and graphic impact to enhance product stand-out and create positive sensory experiences.

Coveris and Pladis partnered to switch to recyclable paper packaging for confectionery (Image credit: Coveris).Lloyd highlights how Smurfit Westrock aims to extend decorations and graphic impact to enhance product stand-out and create positive sensory experiences.

Coveris’s Bonamour explains that, to balance recyclability and barrier performance, the right material is crucial. Flexible plastic packaging remains “vital” for confectionery solutions.

She adds: “Flexible plastic packaging continues to play a vital role in confectionery, where protection from moisture and oxygen is essential to maintain quality and extend shelf life. By preventing spoilage and reducing food waste, high-performance flexible packaging supports a more holistic approach to sustainability.”

Recently, Coveris partnered with Pladis in the US to convert its existing confectionery packaging from non-recyclable oriented PP and paper block bottom bags to fully recyclable paper-based alternatives.

The bags are recyclable within existing recycling streams and meet production requirements, combining machine performance, material strength, and high-quality print.

Bonamour adds: “Crucially, the solution also overcomes long-standing challenges in paper packaging, such as cracking and fiber breakage inside gusset areas.”

Cost concerns

Heightened cost sensitivity can make designing for recyclability challenging, says Smurfit Westrock’s Lloyd. Keeping confectionery costs low is important for snack packaging manufacturers to remain relevant to consumers, he notes.

.webp) Confectionery packaging must balance low costs and experiential consumer experiences, says KM Packaging’s Shipley (Image credit: KM Packaging).KM Packaging’s Shipley says: “Confectionery packaging has a real challenge when it comes to material innovation because it is pulled between the pressures of keeping costs low, and being highly experiential when it comes to the end consumer.”

Confectionery packaging must balance low costs and experiential consumer experiences, says KM Packaging’s Shipley (Image credit: KM Packaging).KM Packaging’s Shipley says: “Confectionery packaging has a real challenge when it comes to material innovation because it is pulled between the pressures of keeping costs low, and being highly experiential when it comes to the end consumer.”

“People want to feel their treat after a hard day is a special moment, and the packaging is part of delivering that promise. Innovation comes from when a material can provide the required ‘wow’ factor while also providing economic or environmental upsides.”

For Coveris’s Bonamour, cost and scale are closely linked to innovation. She explains that advances such as downgauging, the use of innovative materials, and the development of closed-loop recycling systems can reduce reliance on traditional and single-use plastics.

However, she points out, scaling these solutions requires collaboration and investment.

Bonamour argues: “Ultimately, the biggest limitation is not regulation, cost, or material performance alone, but aligning all three.”

“When innovation delivers high performance, recyclability at scale, and a lower carbon footprint, it becomes both commercially viable and compliant — unlocking real progress in confectionery packaging.”