James Cropper tackles color accuracy and circular design with co-created paper packaging

Key takeaways

- James Cropper is addressing color inconsistencies in paper packaging by involving customers in the color-matching process to reduce metamerism.

- The company is balancing circularity with performance by evaluating post-consumer fiber content, virgin fiber strength, surface treatments, emboss patterns, and overall print fidelity.

- The collaboration is said to ensure packaging designs work with material and process variables.

James Cropper is balancing circularity, performance, and aesthetics of paper packaging through co-creation with clients. The company aims to confront the complexity of the modern supply chain with collaborative creativity.

James Cropper is mitigating the effect of metamerism on packaging by including the customer in the color-matching phase to test different formulations under various lighting conditions to find a solution that delivers the desired results consistently.

Metamerism occurs when two colored objects appear to be identical under some lighting conditions, but very different under others.

Stephanie Walker, head of technical at James Cropper, says: “It’s vital for all creative partners to see a sample of their substrate colored using the exact blend of dyes and pigments that will be used in the final production run.”

“Slight deviations in color can have huge implications once the finished product goes into production. Color is much more than it appears to be on a swatch, it’s a system.”

“This is particularly important in packaging applications, as it is well-known that purchasing decisions are influenced by color. We tune hue, saturation, and luminance to the substrates and print processes that are to be used, then build master standards that travel flawlessly from batch to batch, site to site.”

Multi-sensory experience

Co-creation ensures that products are designed, engineered, and proven with the same precision with which they were conceived.James Cropper also weighs the credibility of post-consumer content against the functional strength of virgin fibers, and considers how surface treatments influence print fidelity.

Co-creation ensures that products are designed, engineered, and proven with the same precision with which they were conceived.James Cropper also weighs the credibility of post-consumer content against the functional strength of virgin fibers, and considers how surface treatments influence print fidelity.

The company says it scrutinizes emboss patterns, which refract light and guide touch. Rapid lab trials can be conducted to visualize delta-E tolerances, opacity targets, and ink holdout under real print conditions.

Walker says that when scaled up to full production, the ability to nudge a hue, adjust the depth of an embossed pattern, or fine-tune a formulation can improve the product.

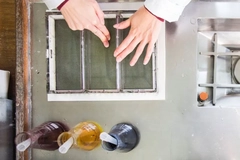

“The best way to make these rewarding decisions is in person. Nothing replaces proximity to the process, whether that is time at the vat watching paper fibers mixed into pulp, or time spent witnessing dyes and pigments mixed into vivid colors in the color lab,” she shares.

“Experiencing all these variables first-hand ensures that creative teams don’t fight against factors like fiber length, water quality, or whitening agents in recycled fiber — they work with them.”