Plant-based film could rival plastic in moisture and oxygen protection, study finds

Key takeaways

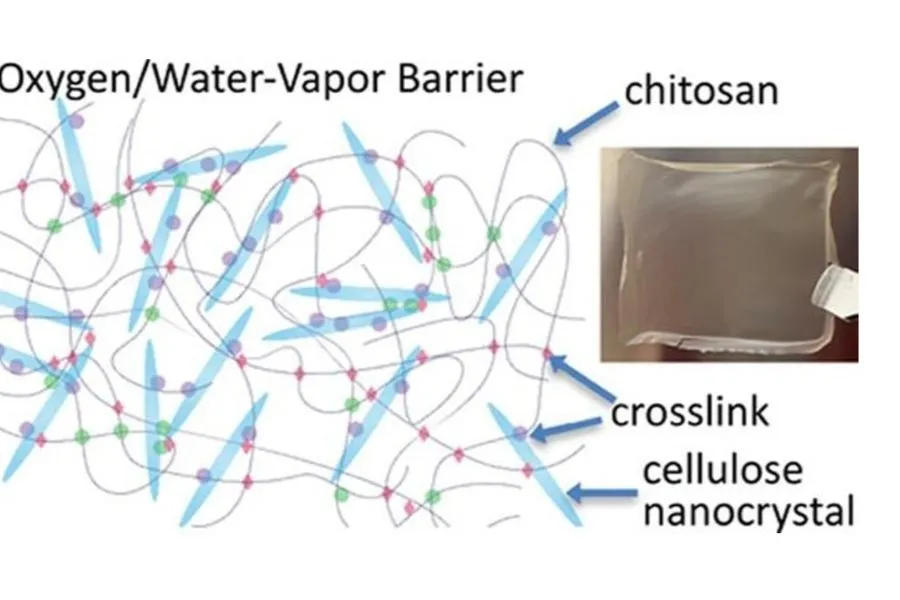

- Researchers developed a biodegradable film from cellulose, chitosan, and citric acid, offering moisture and oxygen protection comparable to conventional plastics.

- The natural ingredients self-organize at the molecular level to form a dense structure.

- The team highlights the potential to scale production by applying the material as a coating on paper or bioplastics.

Researchers at the Georgia Institute of Technology, US, have developed a bio-based film derived from natural ingredients found in plants, mushrooms, and food waste, capable of blocking moisture and oxygen as effectively as conventional plastic packaging materials.

The research, published in ACS Applied Polymer Materials, demonstrates the barrier technology. The solution consists of three primary components: a carbohydrate polymer for structure, a plasticizer to maintain flexibility, and a water-repelling additive to resist moisture.

According to the scientists, when cast into thin films, these ingredients “self-organize at the molecular level to form a dense, ordered structure that resists swelling or softening under high humidity.”

Carson Meredith, a professor at Georgia Tech’s School of Chemical and Biomolecular Engineering and executive director of the Renewable Bioproducts Institute, tells Packaging Insights: “This current study is one in a series of studies over the last several years with the same class of materials. The advance here is the control over moisture barrier properties, which has been a limiting performance property.”

“We’re using materials that are already abundant in nature and degrade there to produce packaging that won’t pollute the environment for hundreds or even thousands of years. I am hopeful that this work will motivate future development and improvements in the same direction.”

Upcycling waste

The biologically based film can be created from natural ingredients.The researchers developed a solution using a blend of natural ingredients: cellulose, chitosan (derived from crustacean food waste or mushrooms), and citric acid (sourced from citrus fruits).

The biologically based film can be created from natural ingredients.The researchers developed a solution using a blend of natural ingredients: cellulose, chitosan (derived from crustacean food waste or mushrooms), and citric acid (sourced from citrus fruits).

By crosslinking these materials and adding a heat treatment, they produced a thin film which is said to be capable of reducing moisture and oxygen transmission — even under hot, humid conditions simulating tropical environments.

The researchers shared that at 80% relative humidity, the films showed “extremely low oxygen permeability and water vapor transmission, matching or outperforming common plastics such as PET and poly(ethylene vinyl alcohol).”

To address the requirements of packaging high-fat or high-moisture products, Meredith notes that the study’s findings demonstrate how the material’s moisture transport rate can be tuned with composition. “This class of materials tends to be able to be tuned to control oil and grease penetration.”

Regarding scaling up the solution, Meredith shares the challenges to be addressed include “minimizing drying time and achieving compatibility with industrial coating equipment. We have ongoing work looking at these aspects.”

“The main way I see these being implemented scalably is by applying the film material as a thinner coating on some other substrate, like paper or another bio-based plastic.”