Key takeaways

- DS Smith collaborates with Raymarine to replace single-use plastic with fiber-based corrugated cardboard for radar product packaging, reducing CO2 emissions by over 60%.

- The new packaging incorporates shock-absorbing crumple zones, air cushions, and reinforced corrugated flutes for protection during transportation.

- The packaging reduces pallet usage by 75%, supports customization, and is fully recyclable, with 84% recycled content.

DS Smith and Raymarine, a manufacturer of navigation systems and electronics for the commercial marine and recreational boating sector, are creating an alternative solution to single-use plastic for Raymarine’s radar product line packaging. The product reduces CO2 emissions by over 60% annually in comparison to the company’s previous packaging solutions.

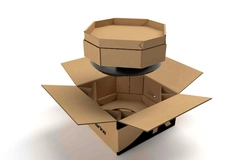

The DS Smith design team has used fiber-based corrugated cardboard materials to replace expanded PE (EPE) foam in Raymarine’s previous solution. The solution ensures maximal transportation protection of radar products against vibrations, unforeseeable physical impacts, and knocks.

Andrew Smith, vice president for Supply Chain at Raymarine, says: “The new packaging ensures that products from our radar range are well-protected during transit while also meeting the demands of diverse climatic conditions and long-haul international shipping.”

Levente Szabó, cluster director at DS Smith Hungary, adds: “We are dedicated to helping our customers in finding solutions for sustainable and circular-ready packaging. When assessing a new packaging design, our process and development research consider the type of materials used, production, transportation, distribution, and supply chain optimization.”

“This packaging for Raymarine is made from 84% recycled content versus 40% in previous packaging, and it is fully recyclable at the end of life. We have successfully replaced EPE, and we can support manufacturers in consumer and industrial sectors.”The structure of the DS Smith packaging contains corrugated cardboard inserts to keep Raymarine’s Quantum radar products secure.

Design specifics

The DS Smith designers have also incorporated a perpendicular-shaped corrugated cardboard flute with a 90-degree angle into the packaging structure to provide built-in strength and a reinforced capacity to withstand shocks.

They have introduced crumple zone layers to deform and absorb energy in the event of any collision, and installed fiber-based air cushions to provide additional optimum support.

The overall structure of the DS Smith packaging contains precisely shaped corrugated cardboard inserts to ensure that Raymarine’s Quantum radar products are held securely in place during any eventuality.

The corrugated cardboard inserts are manufactured using a dedicated folding technique, and within the design is an additional integral box to package product accessories and components separately.

Optimized supply chain process

The new packaging is designed for easy customization and flexibility, and can be produced in various sizes.

Regarding warehousing and distribution processes, the provision of corrugated cardboard inserts in flat packs is said to offer benefits for inbound logistics. The solution reportedly reduces the pallets required by 75% in comparison to previous packaging solutions, where padding components were typically shipped as a single item.

DS Smith designers apply their Circular Design Metrics approach when assessing packaging solutions. The tool identifies a packaging design’s sustainability performance.

It helps to rate and compare the circularity of a packaging design across eight different indicators, including recyclability, renewable content, material utilization, carbon footprint, and supply chain optimization.